CHEMICAL SCIENCES

Type of resources

Keywords

Publication year

Topics

-

The Australian Capital Territory Geochemical Urban Mapping (ACTGUM) project, a collaboration between the National Centre for Forensic Studies at the University of Canberra, Geoscience Australia (GA) and the Australian Federal Police, aims to enable high-quality research investigating the provenancing of topsoil in a law enforcement/intelligence context. Although many geochemical soil surveys already exist, these are typically developed primarily for exploration and related earth sciences, limiting their use for forensic applications that have specific, and often differing requirements (e.g. sampling density, sampling medium and depth, and data treatment). An important part of the project is the development of a high quality, internally consistent, geochemical dataset of topsoil, covering a model area of interest at a relatively high sampling density. Initiated in 2017, a soil geochemical survey has been completed, covering the urban and surrounding suburban areas of Canberra, Australian Capital Territory (ACT), in inland southeastern Australia. At present, a total of 823 topsoil samples (including field replicate samples at 65 sites) have been collected from 686 sites, including 6 resampled sites, which together cover over 650 km2 at the average sample density of 1 site per 1 km2. Samples were collected from urban and suburban public parks, nature reserves, roadside verges, nature strips, and private agricultural land. Obvious areas of anthropogenically introduced, modified or contaminated soils were avoided. At each site, a 1 – 2 kg composite of five subsamples taken from the corners and centre of a 1m x 1m area at a depth interval of 0 – 5 cm was collected, after removal of surface vegetation. All composite samples were subsequently air dried, homogenised and split into two halves. One half was set aside for archiving. The remainder was dry sieved to <75 μm, consistent with existing geochemical surveys in Australia, including the GA National Geochemical Survey of Australia and GA Northern Australian Geochemical Survey. Any excess sample/fraction was kept for potential future use. All subsequent analytical protocols were applied to the <75 μm fraction, and those performed at the GA inorganic laboratory include: (1) X-ray fluorescence (XRF) analysis of fused beads and loss on ignition (LOI) (total geochemistry); and (2) Inductively coupled plasma – mass spectrometry (ICP-MS) analysis of total digestions of fused bead fragments (total geochemistry). Additional and complimentary measurements have been completed elsewhere, including magnetic susceptibility, ICP-MS analysis of aqua regia digests, Munsell soil colour, and X-ray diffraction (XRD) analysis. These measurements have been discussed elsewhere and/or will be published separately. In the present project manual, we describe the: (1) The synopsis underpinning the broader project and determination of sampling sites; and (2) Detailed protocols for sample collection, preparation and analysis of total element content. Release and interpretation of the project dataset, quality assessments and geochemical maps will be published separately.

-

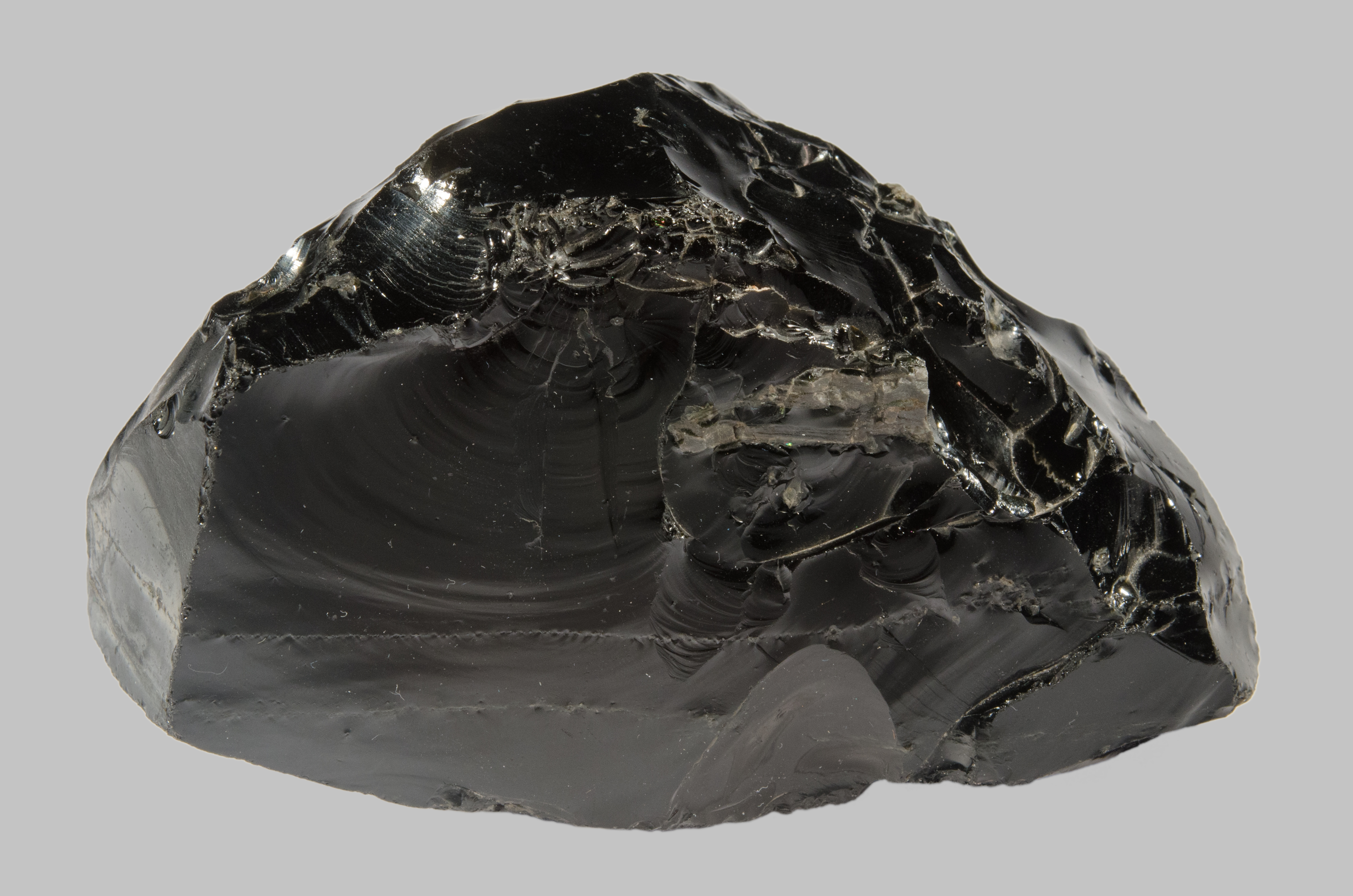

Google Arts and Culture exhibit explaining how man-made and natural glass is formed and the key characteristics of glass. The exhibit features high quality images of fulgurites (glass created by lightning), obsidian (glass from volcanoes) and Australites (glass created by meteorite impacts). The accompanying crossword draws upon content within the exhibit.

-

This activity introduces the concepts of lava viscosity and influence on volcanic cone shape. The download includes background information for teachers and an activity sheet for students. The activity involves making lava slime and racing this down a slope. Participants are asked to predict how lava viscosity might influence volcanic shape (a hypothesis) and then observe what does happen and relate this to the natural environment.

-

Australian iron ore is predominantly exported and used for steelmaking internationally. However, steelmaking is an energy- and carbon-intensive heavy industry, and its electrification in the coming decades will likely disrupt the existing iron ore–steel value chains. Green steel—produced using hydrogen and electricity from renewable energy sources—presents both opportunities and challenges for Australia. Indeed, with abundant renewable energy potential and iron-ore resources, Australia could lead this global transformation. Here, we examine the interrelationships between the Australian iron-ore industry, the production of green-hydrogen from renewable energy sources, and an emergent green steelmaking process. In particular, we undertake detailed case studies to estimate current green steel production costs within two regions; the Pilbara Craton in Western Australia and the Eyre Peninsula in South Australia. While existing technology is not well suited to Australian hematite ores, our analysis highlights the site-specific competitiveness of small-scale, magnetite-fed, off-grid operations. The results underscore the advantages of a well-optimised system in decreasing hydrogen and energy storage requirements, and decreasing production costs. While our results also suggest that grid-connected projects could reduce costs through flexible operation, more work is required to understand the limitations of these conclusions. The results underscore the need to develop technologies to utilise hematite ores in green steelmaking, but also highlight the opportunity for this emerging industry to commercialise Australia’s magnetite resources. <b>Citation: </b>Wang C., Walsh S. D. C., Haynes M. W., Weng Z., Feitz A., Summerfield D., & Lutalo I., 2022. From Australian iron ore to green steel: the opportunity for technology-driven decarbonisation. In: Czarnota, K. (ed.) Exploring for the Future: Extended Abstracts, Geoscience Australia, Canberra, https://dx.doi.org/10.26186/147005